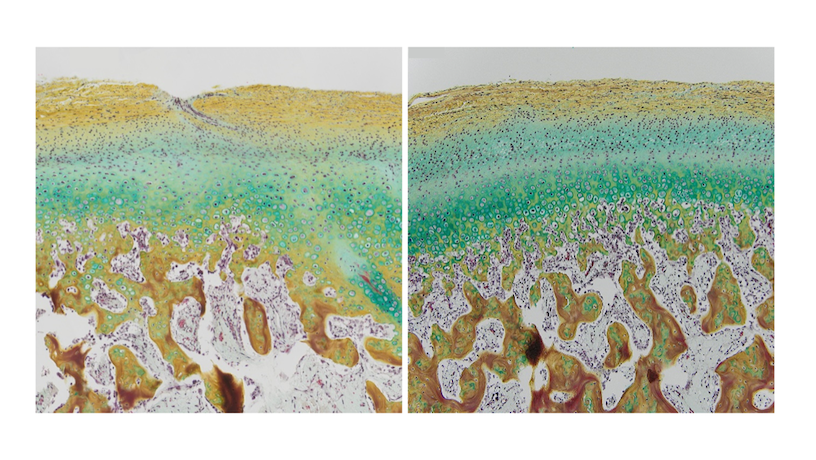

Stratification of the cartilage layer – Detailed morphology of the bioengineered graft 6 months after implantation (left) compared to the native joint (right). Distinct fibrous, proliferative and hypertrophic zones in the cartilage layer are well established. Stain: pentachrome.

New York, NY—October 14, 2020—The temporomandibular joint (TMJ), which forms the back portion of the lower jaw and connects your jaw to your skull, is an anatomically complex and highly loaded structure consisting of cartilage and bone. About 10 million people in the United States alone suffer from TMJ dysfunction due to birth defects, trauma, or disease. Current treatments range from steroid injections that provide only a temporary pain relief, to surgical reconstructions using either prosthetic devices or donor tissue, and often fail to provide long-lasting repair. Researchers have sought a better way to treat TMJ, including investigating biological TMJ grafts grown in the lab that could integrate with the native tissues, remodel the joint over time, and provide life-long function for the patient.

A multidisciplinary team from Columbia Engineering, Columbia’s College of Dental Medicine and Department of Medicine, Louisiana State University, LaCell LLC, and Obatala Sciences has now bioengineered living cartilage-bone TMJ grafts, precisely matched to the recipient, both biologically and anatomically. Their most recent study, published today in Science Translational Medicine, builds upon a long series of their previous developments that began in 2005 on bioengineering functional cartilage and bone for regenerative medicine and tissue models of disease.

The authors used the Yucatan minipig to establish their methodology for TMJ reconstruction using the recipients’ own cells. The team isolated the stem cells from a small amount of fat obtained from each animal, expanded the cells in culture to obtain a sufficient number for a large graft, and induced them into the cartilage and bone- forming cells. Using imaging-guided fabrication, the researchers shaped a block of clinically used decellularized bovine bone matrix into the exact geometry of the TMJ being repaired. They infused this scaffold with bone-forming cells, while inducing cartilage formation by compacting a 1-mm thick surface layer of condensed mesenchymal cells. They built the matching bioreactor chamber so that the scaffold fitted tightly into it, like a hand in a glove.

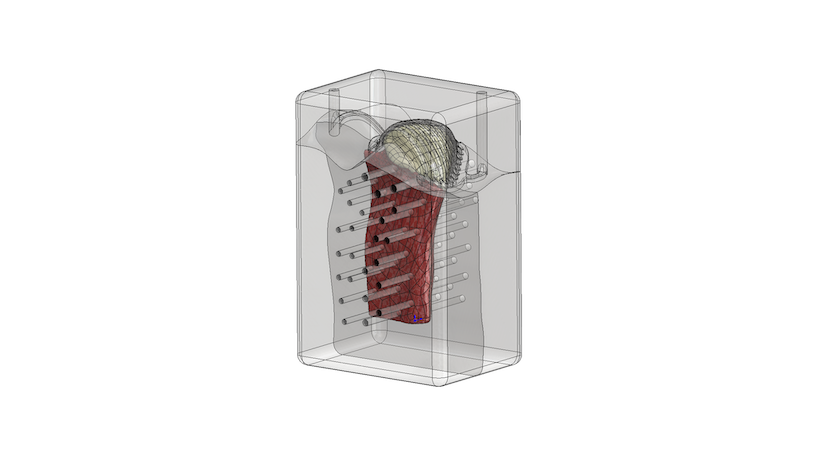

Bioreactor design: Schematic of cartilage-bone graft in bioreactor.

Overall structure of the bioengineered joint – Overall morphology of the bioengineered temporomandibular joint 6 months after implantation (left) compared to the native joint (right). The cartilage and bone regions are clearly established.

Because cartilage and bone form under different environmental conditions, the formation of TMJ grafts required a specialized bioreactor that provided a separate supply of bone and cartilage culture media to the two tissue regions. The researchers optimized perfusion of culture medium through the bone and flow over the cartilage surface in order to meet the distinctly different nutrition and physical signaling requirements of the two tissues. Once all these demanding conditions were met, the team implanted the individualized TMJ grafts into the experimental animals for six months to determine the grafts’ ability to structurally and functionally replace the native joint.

“What we found in this new work could be transformative,” says the team’s PI Gordana Vunjak-Novakovic, University Professor, The Mikati Foundation Professor of Biomedical Engineering and Medical Sciences, and Professor of Dental Medicine. “These grafts had a native-like stratified appearance, integrated well with the surrounding tissues, and provided the biological and mechanical function of the native joint. We believe that this methodology could be extended to bioengineering other joints, and to establishing high-fidelity models for studying joint diseases.”

Vunjak-Novakovic noted that the size and profile of the multi-institutional research team of 18 investigators with expertise in bioengineering, surgery, stem cells, imaging, bioreactor design, and mathematical modeling reflects the complexity of this translational project, which took four years to complete.

The use of the dual-flow bioreactor was critical to the study. “Developing this one-of-a-kind bioreactor was instrumental for the formation of composite cartilage-bone grafts,” says Vunjak-Novakovic. “Each tissue was maintained within its own ‘niche,’ while allowing communication between cartilage and bone by diffusing factors, just like in our body. Acommodating the complex shape of the TMJ was an additional difficulty we needed to overcome, through creative experimentation and modeling studies.”

Study lead authors David Chen and Josephine Wu, biomedical engineering PhD students who work in Vunjak-Novakovic’s lab, add, "Seeing the evolution of our tissue grafts was tremendously exciting. Each stage felt like a milestone, from achieving a nascent, thin layer of cartilage in the lab, to the first glimpse after implantation into the healed joint space, complete with a fully formed, stratified cartilage.”

Coincidentally, the study is being published at the time when epiBone, a company launched from the Vunjak-Novakovic lab to develop a pipeline of bone, cartilage, and composite bone-cartilage products, is starting a Phase I/II clinical study to evaluate its bone product in patients with lower jaw continuity defects that require reconstruction. This clinical trial is designed to create living bone grafts that can become a seamless part of a patient's body, based on the same foundational technology as the present study.

The investigators emphasize that more work needs to be done before patient-tailored TMJ grafts can become a clinical reality. Studies over longer periods of time are needed to fully understand the progression of tissue remodeling. In addition, the researchers are interested in extending their methodology to exploring the diversity of the patient population and investigating TMJ repair as a function of age, sex, or the presence of skeletal disease or relevant systemic conditions.

BY HOLLY EVARTS | IMAGE CREDIT: DAVID CHEN AND JOSEPHINE WU/COLUMBIA ENGINEERING